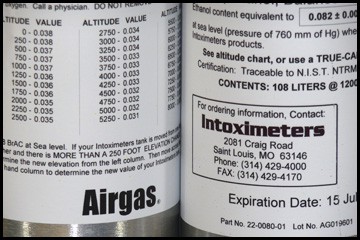

Dry Gas Standard

|

Intoximeters recommends that external accuracy checks and calibrations be performed using either a dry gas or wet bath standard approved for use by both NHTSA and Intoximeters. (Wet bath simulators should be used with properly certified and maintained ethanol solutions). To ensure that they produce consistent and reliable samples, compressed gas tanks, simulators and simulator solutions should be used and maintained in accordance with the quality assurance plans provided by their respective manufacturers to ensure that they produce consistent and reliable samples. Approved Dry Gas Standard ELEMENTS:

|

|||||||||||||

|

The table below shows the estimated number of tests that you would get out of a full tank, if you ran it until it was empty.

Assumes 8 seconds gas flow time

GENERAL INFORMATION:

|

|

||||||||||||

|

OPERATING GUIDELINES:

|

|

||||||||||||

|

Note: When removing the old “0” ring DO NOT CUT IT OFF WITH A SHARP TOOL – this might mar the threads and cause future “0” rings to be damaged.

|

|

||||||||||||