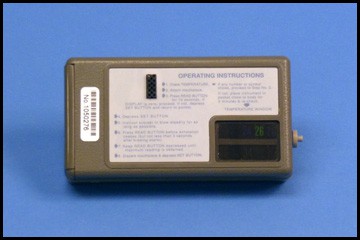

Alco-Sensor III Accuracy Check Procedure

Tools Required: Before beginning have items available: instrument, calibration standard, new mouthpiece

Alco-Sensor III Accuracy Check Procedure Part 1

|

|

Note: A calibration standard can be a:

|

|

For this demonstration, a dry gas cylinder is used as the standard – value (at sea level) of.082%.

|

|

Alco-Sensor III Accuracy Check Procedure Part 2

Accuracy Check – Alco-Sensor III

|

Temperature window display |

|

READ button depressed ASIII displays .000 |

|

SET Button Pressed |

|

|

Alco-Sensor III Accuracy Check Procedure Part 3

|

|

through the mouthpiece until one second after the read button is depressed).

|

Submit a gas sample  READ button is depressed |

|

Observe the final result |

To demonstrate compliance with your program’s QAP it is best to keep a record or a Calibration Log for each device used for testing. The log should contain the results of all accuracy checks and calibrations for each instrument. This log may become a crucial piece of evidence should your test results be challenged. The log may include information such as:

- Date

- Time

- Procedure performed (Accuracy Check or Calibration)

- Name of Technician performing procedure

- Location

- Identification of the Standard including Lot Number of the Standard

- Expected Value of the Standard

- Result of the Accuracy Check or Calibration

For more information about procedures for your Intoximeters instrument, please refer to your

- Operator’s Manual

- or email Intoximeters Tech Support

- or phone the Technical Support Department at 314-429-4000