Alco-Sensor VXL Accuracy Check Procedure

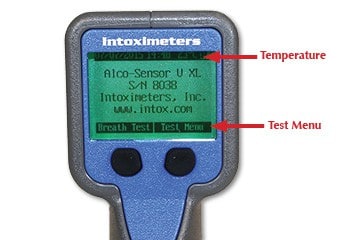

Please note that the display screens for performing accuracy checks on the Alco-Sensor VXL may vary by software version. The test sequence described here may be slightly different than the sequence on your ASVXL device. We will be demonstrating the procedure on the General Screener version of the ASVXL.

Prior to running an Accuracy Check you should make certain that the Standard you will be using is current and all of the operating parameters for that device have been met:

- Have as little tubing as possible between the gas out port of the standard and the mouthpiece of the Alco-Sensor VXL.

- Check Expiration Date (on Wet Bath Simulator Solution or Dry Gas Tank)

- Check temperature of the Wet Bath Simulator (if used)

- If using a Dry Gas standard, ensure the tank is at room temperature

- Purge the simulator tubing or dry gas regulator for several seconds

- Know the current expected value of the Standard

- If you keep a calibration log, it should be present

Ensure the tools listed below are present:

- Dry Gas Standard

- Regulator with a 6 Liter Per Minute regulator and mouthpiece adapter

- True-Cal or True Cal II Device (if used)

- Alco-Sensor VXL

- New Mouthpiece

Note: A calibration standard can be a:

-

- Dry Gas Cylinder and Regulator

- Wet Bath Simulator and Solution

For this demonstration, a dry gas tank is used as the standard – value (at sea level) of .082%. a True-Cal Device was used to give the expected value of the standard at the time of our demonstration – the True-Cal will show the expected gas value adjusted for the current atmospheric pressure. Therefore, the target value for this demonstration is .080.

Alco-Sensor VXL Accuracy Check Procedure Part 1

|

|

|

Scroll to Main Menu  Enter your Password  Choose Quality Assurance from the Main Menu |

NOTE: Wet Bath Simulator users will not be asked about the Target Value since the Standard and Target values for a wet standard are the same. |

Target value of standard  |

|

|

|

|

|

Alco-Sensor VXL Accuracy Check Procedure Part 2

|

|

|

Connect mouthpiece to regulator hose  As gas is flowing through the 6LPM regulator, the red lights will illuminate |

|

|

| If your device is set up to communicate to a printer, then you will be prompted to place the ASVXL into the Docking Cradle for printing. If you are not set up for printing, then the accuracy check sequence will end at this point. | |

Accuracy Check – Alco-Sensor VXL Record Keeping

To demonstrate compliance with your program’s QAP (Quality Assurance Plan) it is best to keep a record or a Calibration Log for each device used for testing. The log should contain the results of all accuracy checks and calibrations for each instrument. This log may become a crucial piece of evidence should your test results be challenged. The log may include information such as:

- Date

- Time

- Procedure performed (Accuracy Check or Calibration)

- Name of Technician performing procedure

- Location

- Identification of the Standard including Lot Number of the Standard

- Expected Value of the Standard

- Result of the Accuracy Check or Calibration

For more information about procedures for your Intoximeters instrument, please refer to your

- Operator’s Manual

- or email Intoximeters for Technical Support

- or phone the Technical Support Department at 314.429.4000

For additional maintenance information please click here.