Alco-Sensor FST Accuracy Check Procedure

An Accuracy Check should be performed periodically. The frequency should be determined by your Quality Assurance Program.

Prior to running an Accuracy Check you should make certain that the Standard you will be using is current and all of the operating parameters for that device have been met:

- Have as little tubing as possible between the gas out port of the standard and the mouthpiece of the Alco-Sensor FST.

- If using a Wet Bath or Dry Gas Standard check the expiration date

- If using a Wet Bath Standard check the temperature

- Purge the simulator or dry gas regulator for several seconds

- Know the current expected value of the Standard gas by using a True-Cal (II) or Elevation Chart

- If you keep a calibration log, one should be maintained for each Alco-Sensor FST

Tools Required: Before beginning have items available: instrument, calibration standard, new mouthpiece

FST Accuracy Check Procedure Part 1

|

|

Note: A calibration standard can be a:

For this demonstration, a dry gas cylinder is used as the standard – value (at sea level) of.082%. A True-Cal II device was used to give the true value of the standard at the time of our demonstration – the True-Cal II shows the expected gas value adjusted for the current atmospheric pressure. Therefore, the target value for this demonstration is .081 |

True-Cal displays .081 |

| Note: While wet bath Standard accuracy checks can be performed throughout the full instrument temperature range of 0ºC – 50ºC, if you are using Dry Gas as your Standard for accuracy checks, then the unit and gas should be at or between 10ºC and 40ºC.The result of an accuracy check should not differ from the expected value by more than the tolerances prescribed by the program guidelines under which the Accuracy Check is being administered. Usually these tolerances range from ± .005 g/210L or 5% whichever is greater, to ±.010 g/210L or ± 10% whichever is greater. | |

FST Accuracy Check Procedure Part 2

| 1) Attach a new mouthpiece then press and hold the OFF button while simultaneously pressing the ON button. |  |

| 2) The display should show the rcL message (this is the first option in the function Menu)Note: After gaining access to the instrument menu indicated by rcL being displayed – pressing the ON button will allow you to scroll through the list of available options – rcL, PAS, rbL, ACC, CAL, dSr. Pressing the OFF button will execute or select the option displayed at the time the; OFF button is pressed. |  |

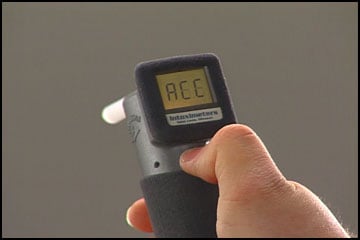

| 3) Momentarily depress the ON button until the displayed message changes to ACC. |  |

| 4) With;ACC on the display, press the OFF button to select the Accuracy Check option. (The temperature will be displayed followed by bLN and the result of the blank test). A flashing ACC message will be displayed.

Note : Make certain you have purged the dry gas regulator for several seconds. |

|

FST Accuracy Check Procedure Part 3

| 5) While the display shows a flashing ACC, make an airtight connection between the delivery tube of the regulator and the open end of the mouthpieces. |  |

| 6) Depress the regulator control button.

7) When there is a continuous airflow – 6 liters per minute for four seconds – the instrument should capture a sample automatically. Make certain that the gas continues to flow for 1-2 seconds after the sample is captured. (Sample collection is identified by a clicking sound.) (Note: If for some reason you cannot provide an adequate flow rate for the instrument to collect an automatic sample, it is possible to perform an Accuracy Check by taking a manual sample. To perform an Accuracy Check in this manner, depress the regulator control button and have the gas flowing to the instrument for seven seconds. On the 5th second depress the ON button to take a manual sample. Make certain that the gas continues to flow for 1-2 seconds after the sample is taken.)

|

|

| 8) Detach the mouthpiece from the regulator.

9) Observe the results and compare it to the known value of the Standard gas.

|

|

| 10) If the displayed result (as compared to the known value of the Standard gas)does not meet your programs specified tolerances, the unit will require a calibration adjustment. If the result is within the required tolerances, the procedure is complete.11) Record the results in your calibration log book. |  |

Accuracy Check – Alco-Sensor FST Record Keeping

To demonstrate compliance with your program’s QAP (Quality Assurance Plan) it is best to keep a record or a Calibration Log for each device used for testing. The log should contain the results of all accuracy checks and calibrations for each instrument. This log may become a crucial piece of evidence should your test results be challenged. The log may include information such as:

- Date

- Time

- Procedure performed (Accuracy Check or Calibration)

- Name of Technician performing procedure

- Location

- Identification of the Standard including Lot Number of the Standard

- Expected Value of the Standard

- Result of the Accuracy Check or Calibration

For more information about procedures for your Intoximeters instrument, please refer to your

- Operator’s Manual

- or email Intoximeters for Technical Support

- or phone the Technical Support Department at 314.429.4000